Fiery R&D—An Insider’s Look

Introduction

As the print industry leader in digital front-end (DFE) technology, our goal is to make digital printing efficient, accurate, and of exceptional quality. In Fiery R&D—An Insider’s Look, we highlight how Fiery DFEs set the standard in the print industry through five central pillars of innovation: processing power, performance, color, user experience, and integration.

In this post, we share how our innovations, technology, and solutions support print providers’ evolving needs and enhance the printing ecosystem.

Processing Power

Fiery DFEs offer innovative designs that combine hardware and software into solutions for efficient, high-quality printing. Our proprietary application-specific integrated circuits (ASICs) accelerate image processing, deliver outstanding speed, and reduce dependence on expensive general-purpose computing hardware – a key differentiator from other print technology companies.

Equipped with these advanced hardware platforms, our DFEs are engineered to address the broad range of image-processing requirements for next-generation print systems – from outstanding quality to complex variable data requirements.

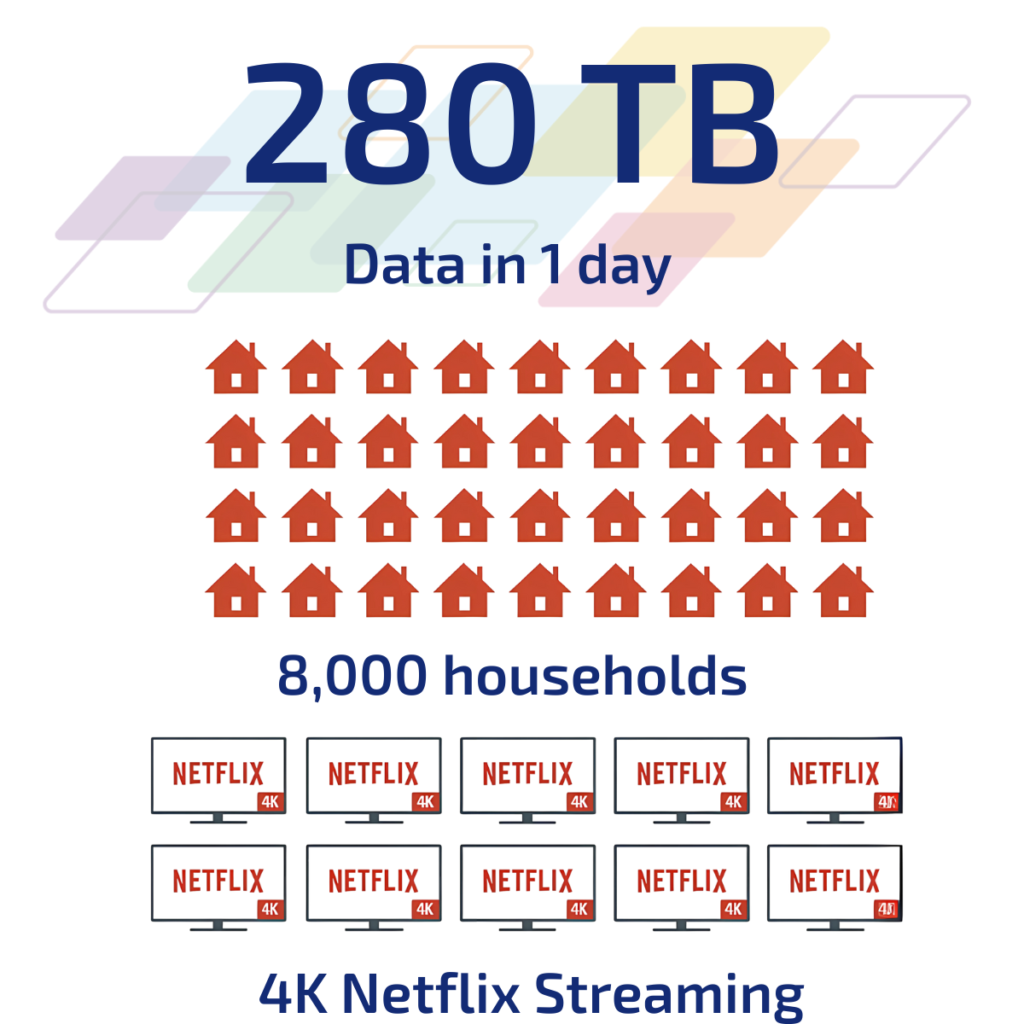

Today, one Fiery DFE image processing unit can handle over 280 TB of data per day—equal to 8,000 households streaming 4K Netflix movies simultaneously.

Beyond the unique processing power advantage from our algorithms and integrated hardware/software architecture, Fiery approaches innovation in digital print technology through four key categories:

Performance

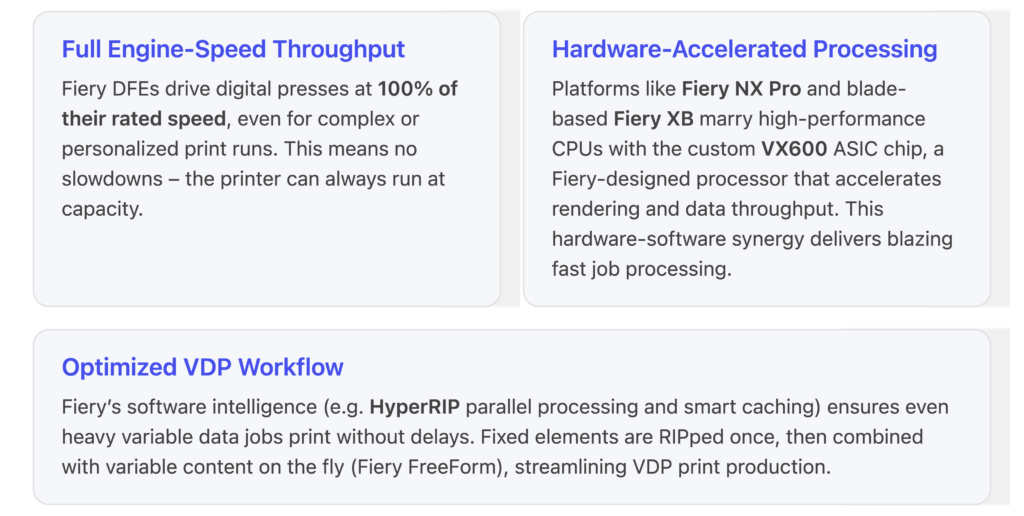

At Fiery R&D, we strive to give printers powerful DFEs that help them perform to their fullest potential. This means keeping machines running at their highest rated speeds, while achieving maximum print quality – even for their most challenging complex print jobs.

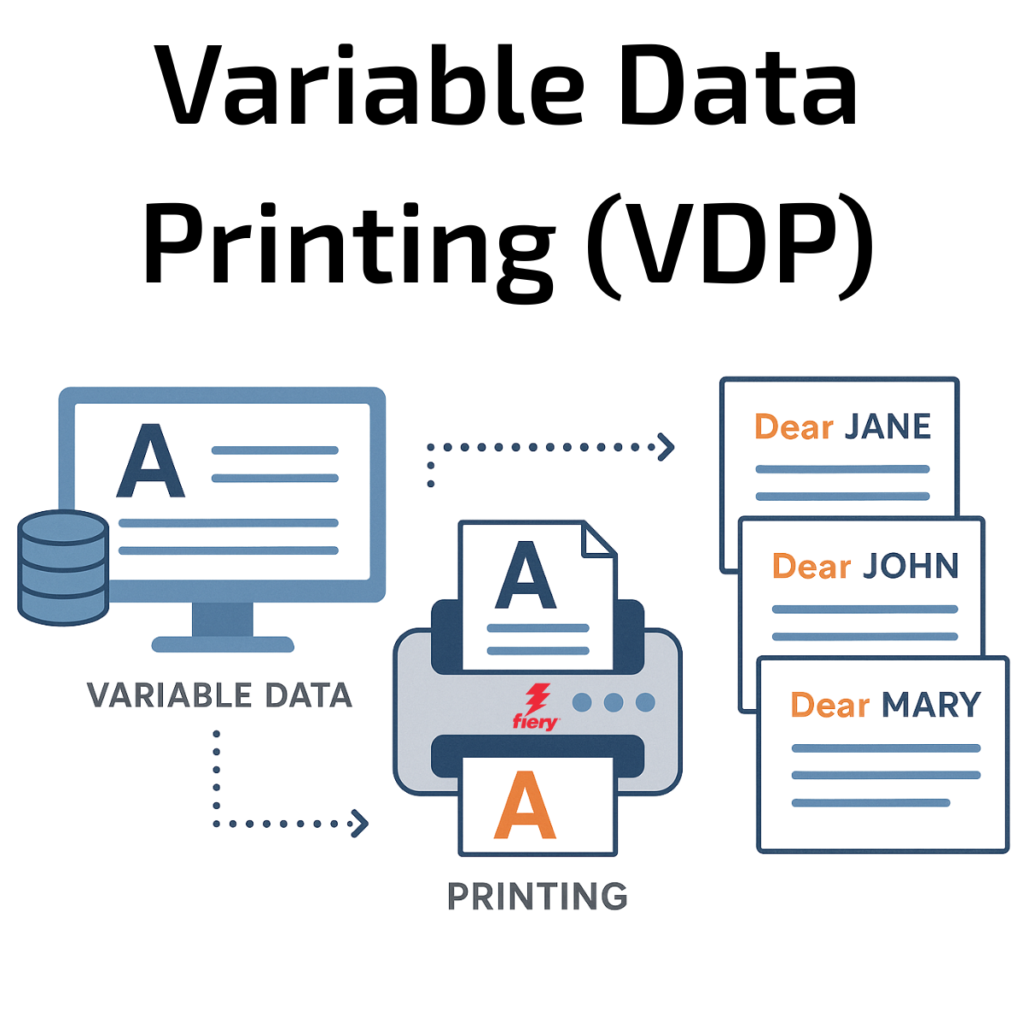

Variable data printing is a core advantage of digital printing. Since Fiery started to solve problems in digital printing, variable data printing is one of the core strengths of Fiery’s technology.

Fiery has been innovating solutions in variable data printing (VDP) for decades, efficiently processing VDP jobs to ensure quick and accurate output of personalized documents. Fiery has the most versatile VDP format capabilities in the print industry – developed over three decades of R&D. Our proven track record of accurate handling of overprint and transparencies combined with variable content has been made clear through years of surpassing industry standards and glowing customer testimonials.

Our advanced variable data storage and caching can handle the most demanding VDP jobs, often processing data dozens of times faster than other RIPs. Fiery is known for its powerful and easy VDP workflow, such as FreeForm Create, that lets print operators build VDP jobs easily.

As the print landscape evolves, VDP applications are expanding beyond mailers and business documents into packaging and labels. Our smart scaling technology is an example of how we’re innovating in these industrial print markets. Imagine printing custom-sized boxes where every design, barcode, or address can dynamically adjust to fit any box size—without needing to redesign layouts manually. This is the real-world problem-solving that Fiery R&D worked on with teams from Packsize and EFI for the X5 Nozomi, and is only possible with a DFE capable of managing large amounts of variable data through lightning-fast RIP and imaging speeds.

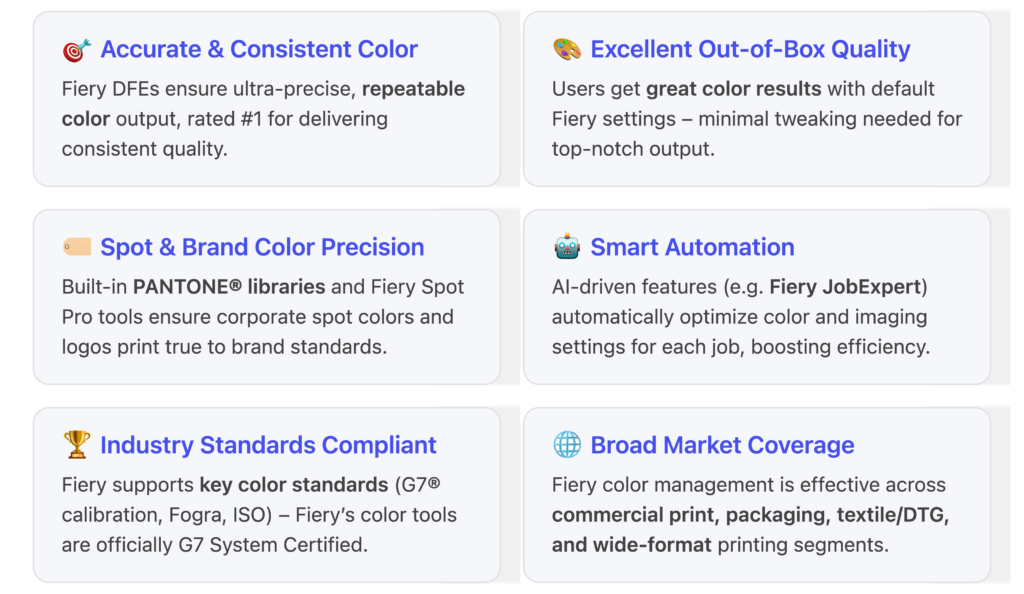

Color

Fiery first introduced an integrated color management system back in 1991. Since then, Fiery has developed many advanced color technologies, secured more than one hundred patents in color management, and delivered a range of industry-leading solutions. At Fiery R&D, our global team of color & imaging scientists and software developers is focused on four key areas that we believe are most important for our customers: precise & consistent color, outstanding out-of-box print quality, brand color accuracy, and intelligent automation to make color easy.

Fiery color management provides a comprehensive, field-proven system that brings together scientific rigor, practical innovation, and industry alignment. Its key strengths – from accurate and consistent output to powerful spot color handling and automation – empower users across commercial, packaging, textile, and large format printing to produce top-tier results. Meanwhile, Fiery’s relentless pursuit of excellence is evident in how we’ve pioneered solutions for each print segment, ensuring that whether you’re printing a brochure, a cereal box, a custom T-shirt, or a trade show banner, your Fiery DFE delivers the color exactly as intended.

Importantly, Fiery achieves this while adhering to the highest color standards of our industry, giving users confidence that “Fiery color” means world-class accuracy and reliability. With a Fiery DFE at the heart of your printer, you can tackle demanding jobs and new market opportunities knowing that the color will be right – and in the world of print, that assurance is gold.

User Experience

Print operators often face the challenge of juggling multiple job management systems – especially in shops running a mix of printers from different manufacturers. Each device might have its own interface and workflow quirks, making production both complicated and time-consuming to learn. Fiery R&D user experience (UX) experts have turned this complexity on its head with a user-centric approach to digital print management.

Fiery Command WorkStation, widely regarded as the industry’s gold standard for print job management, provides a single unified platform that lets you control every printer in the shop – whether it’s an A3+ cut-sheet toner press, a large-format printer, or a high-speed inkjet press – all through one intuitive interface. Command WorkStation delivers maximum control with minimum effort, consolidating diverse equipment under one easy-to-use system

By centralizing the print room in this way, Fiery DFEs dramatically reduce the time and training needed to run a successful production environment. Operators no longer need months to master various vendor-specific tools; with Command WorkStation’s consistent, intuitive experience, even new or less-experienced staff can get up to speed quickly. This is especially valuable given the industry’s shortage of skilled print operators – a gentler learning curve means new employees become productive in far less time. In short, Fiery’s focus on user experience empowers print businesses to work more efficiently and adapt faster. A unified Fiery workflow not only streamlines daily tasks and reduces errors, but also saves valuable time and resources, helping your print shop meet deadlines and grow business with confidence.

Integration

A core concept at the heart of our R&D philosophy is that innovation can’t happen in isolation. Whether it’s presses from different manufacturers, or the complex array of finishing devices in a print room, or even business systems that help you monitor performance and keep inventory stocked, managing all the different devices in a print shop can be a daunting task if those devices don’t play nicely together.

At Fiery, we work with more equipment manufacturers than any other competitor in the print industry – virtually all major printer manufacturers – to create solutions that integrate all the different devices in a print shop, from printers to cutters to inventory management to business analytics systems.

Our Fiery IQ business analytics platform, for example, provides a cloud-based system to analyze print data – everything from workflow automation to printer health to ink inventory. Accessed through Fiery Command WorkStation, Fiery IQ gives you a window into the performance of all the different devices in your shop in an easy-to-understand way. As always, our goal is to enhance efficiency and minimize operator effort, delivering solutions that make the operational side of printing as streamlined as possible so you can focus on the growth you care about.

Check out our recent Fiery IQ webinar to know more.

Leading The Way to a Smarter Future

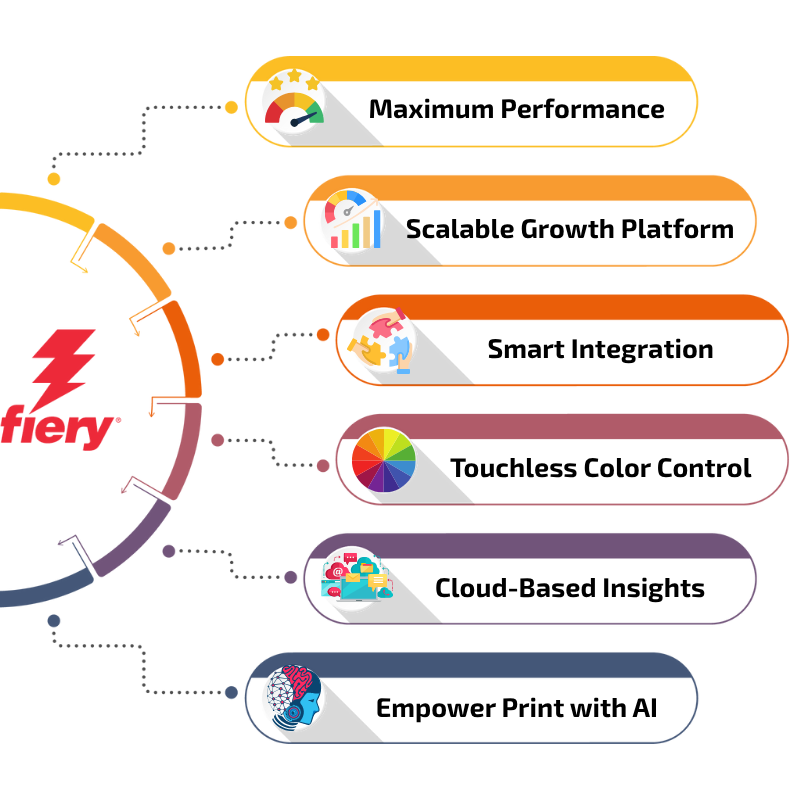

Looking ahead, the print shop of the future will be smarter, more automated, and more interconnected. AI, robotics, and cloud technology will power intuitive printing, enabling real-time quality adjustments and hands-free operations. This shift will increase operator power, reduce waste, minimize downtime, and maximize output—all while maintaining impeccable quality.

Maximum Performance: Fiery DFEs are the fastest in the print industry, accelerating device performance with pinpoint accuracy and intelligent adjustments that keep your print shop running at its highest potential.

Scalable Growth Platform: A digital printing platform like Fiery Command WorkStation is designed to scale effortlessly to support maximum growth, regardless of the size of your print business.

Smart Integration: Fiery’s focus on integrating all the devices in your print room delivers an intelligent print ecosystem—from job submission to prepress to finishing devices – giving operators full control over the entire end-to-end print workflow.

Touchless Color Control: Tools like Fiery ColorGuard automatically verify, correct, and maintain color output across all your print devices—delivering touchless color control for maximum accuracy on each job.

Cloud-Based Insights: The cloud-based Fiery IQ™ data analytics suite gives instant access to cloud-based performance analytics and production insights, helping you maximize your efficiency from both equipment and supply purchases.

Empower Print with AI: AI-native systems like the upcoming Fiery JobFlow Pro will help operators manage print processes through natural language interaction at their own skill levels – making the job of printing intuitive, effortless, and highly effective.

At Fiery R&D, we aim to empower customers by delivering the best technology for the best possible print results. Whether through our industry-leading color management, high-speed VDP capabilities, or AI-powered innovations, we’re shaping the future of digital printing and helping print shops achieve superior results with the industry’s leading print technology at the heart of their operations.