Color Management vs. Color Control: What’s the Difference?

The distinction matters in today’s print workflows

If you’ve ever had a customer call and ask why their logo looks “a little too red” or why a reprint doesn’t match the last job, you already know how important color is to customer satisfaction. In the realm of digital printing, comprehending Color Management vs. Color Control can make all the difference. But getting color right — and keeping it consistent — can be an ongoing challenge. Understanding the differences in color management vs. color control in digital printing is crucial for delivering the stellar color results your customers rely on.

Though they sound similar, and are often used interchangeably, color management and color control are not the same. And that distinction matters — especially today, when commercial print shops are dealing with fewer trained staff, tighter turnaround times, and more complex digital workflows. As a leading color technology expert in digital printing, Fiery is here to set the record straight and show you how to master both color management and color control to get the color quality that makes people take a second glance.

Color management gets the color right

Color management is all about getting to the right color when you start. That means dialing in your printer, media, ink or toner, and measuring the color output to make sure the color looks the way it’s supposed to. You’re essentially creating a profile that captures what “good color” looks like for a specific setup.

It’s like setting a GPS before a road trip. You define the destination — accurate color — and color management plots the most efficient and repeatable route to get there.

Tools like Fiery Color Profiler Suite make this setup easier, especially if your press has an inline spectrophotometer. With just a few clicks, the system prints, measures, and creates the ICC profile for that specific printer and media. Need G7 compliance? It’s built in. No manual tweaking required. No guesswork.

But here’s the challenge: you can’t treat this step as a one-and-done. If you create a profile and the output looks great, you can’t leave it untouched for weeks or months. That’s because variables like environmental conditions, toner batches, and printer wear start to drift. That once-perfect color profile no longer holds up this time around – meaning now you have to move on to color control.

Color control keeps it that way

Color control is the part that most people overlook. It’s what keeps your color consistent after you’ve set up the profile. Think of it like regular maintenance for your car — you don’t tune it once and expect it to run perfectly forever.

In printing, things shift over time. The temperature changes. Humidity swings. Your toner batches might vary. Over time, those tiny variations add up, and that spot-on color you nailed a few weeks ago starts to diverge from what you intended.

That’s where color control comes in. It’s the process of regularly checking and correcting your output to make sure it’s still in spec. Print a test chart, measure it, compare the results, recalibrate if needed. The importance of management versus control in digital printing cannot be overstated.

In theory, it sounds simple. But in practice, manual color checks can be time-consuming. And finding staff with the expertise to do it correctly? That’s getting tougher. This is where automation can make a real impact.

Hands-free color control with Fiery ColorGuard

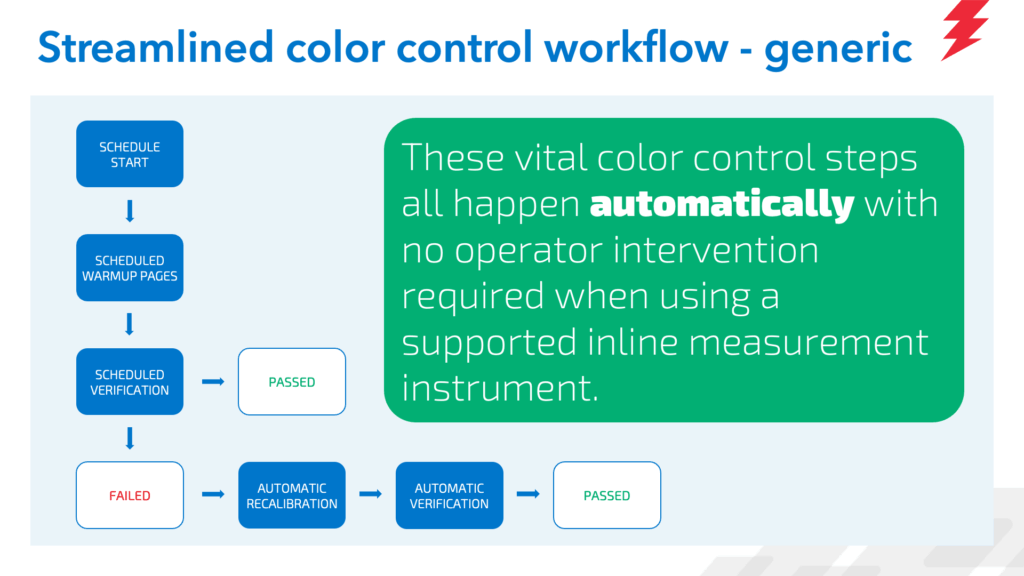

The newest version of Fiery ColorGuard takes color control from a manual hassle to a fully automated, behind-the-scenes process. Designed to work seamlessly with inline measurement instruments in presses, it verifies, corrects, and maintains color output across your devices without stopping production or requiring operator input.

It’s a significant advancement in digital printing automation. Fiery ColorGuard removes the need for manual checks, warmup jobs, and unnecessary recalibrations. When paired with Fiery’s streamlined color management tools that combine media calibration and profiling into a single step, Fiery now offers the most automated end-to-end solution for achieving and maintaining high-quality color across your entire shop.

Here’s what ColorGuard automates:

- Scheduled color verification

- Recalibration only when needed — saving time, toner, and effort

- Brand spot color checks for color-critical jobs

- Real-time color status using clear traffic light indicators

- Universal verification for media that share the same calibration

Why it matters?

In today’s fast-paced, high-pressure print environment, automated color control isn’t a nice-to-have: it’s essential. When there’s no time for manual checks and no trained color expert on standby, ColorGuard ensures color quality doesn’t suffer in the ongoing battle of delivering the right colors to your customers.

With ColorGuard in place:

- You catch color drift before it becomes a problem

- You reduce waste and avoid unnecessary downtime

- You maintain brand consistency across reorders

- You free up your team to focus on running jobs, not chasing color

It’s like having a built-in color expert who works 24/7 and never misses a check. That kind of reliability translates directly to better quality, happier customers, and fewer surprises on the press line.

Simplify and automate color today

Getting accurate color is one thing. Keeping it that way across devices, shifts, and repeat jobs is another. But with Fiery ColorGuard, color control no longer has to be manual, time-consuming, or dependent on a single staff member.

This fully automated solution reflects Fiery’s broader commitment to pushing digital print innovation forward. For over 30 years, Fiery has led the industry in color science, workflow integration, and automation, helping print shops of all sizes deliver reliable, high-quality output — all with ever-growing levels of efficiency and user ease.

Thanks to Fiery ColorGuard, which builds automation into every step — from setup to ongoing verification — it’s never been easier to stay in control of your color, with both color management and control processes integrated seamlessly.

Watch our latest video to learn more about Fiery ColorGuard and automatic color control, or listen to our Podcast for an in-depth discussion about the topic.