30 Years of Fiery Leadership

Introduction

In 1991, Fiery made history by connecting an office copier to a computer for the first time ever. This innovation led to the world’s first digital front end (DFE) and set the stage for a revolution in digital printing – a groundbreaking moment that didn’t just redefine what a copier could do but ignited a three-decade-long journey of digital print innovation. This journey continues to pivotally shape the printing and graphic arts industries today.

For the past three decades, Fiery has led the world in DFE technology. We understand what drives innovation in the print industry. And we think it’s time to share what we’ve learned along the way.

In this new blog series, we’re giving you an inside tour of Fiery’s innovation engine, our experts, and our way of thinking.

We’ll cover everything from the ins and outs of DFEs to product deep dives. We’ll also share Fiery’s uniquely broad perspective on key trends in the print industry.

Three decades of digital print innovation

Over 30 years ago, Fiery transformed the printing landscape by introducing the first commercially successful RIP technology. This innovation bridged the gap between graphic design software and digital color printers. This revolutionized how digital files were processed, laying the groundwork for today’s high-speed, high-quality printing. From that first RIP, Fiery has remained at the forefront of digital printing, introducing industry firsts that have delivered quantum leaps in the capabilities of printers across a wide range of industries.

Did you know what Fiery came up with?

- We introduced the first integrated color management system, ensuring consistent, accurate colors across diverse media.

- We were the first to offer real-time production management with Fiery Command WorkStation, enabling operators to control jobs, devices, and color from a single interface.

- We led the way in integrating Variable Data Printing (VDP), spot color matching, server-based imposition tools, cloud-based analytics, and APIs for DFEs.

- We pioneered end-to-end workflow automation with Fiery JobFlow.

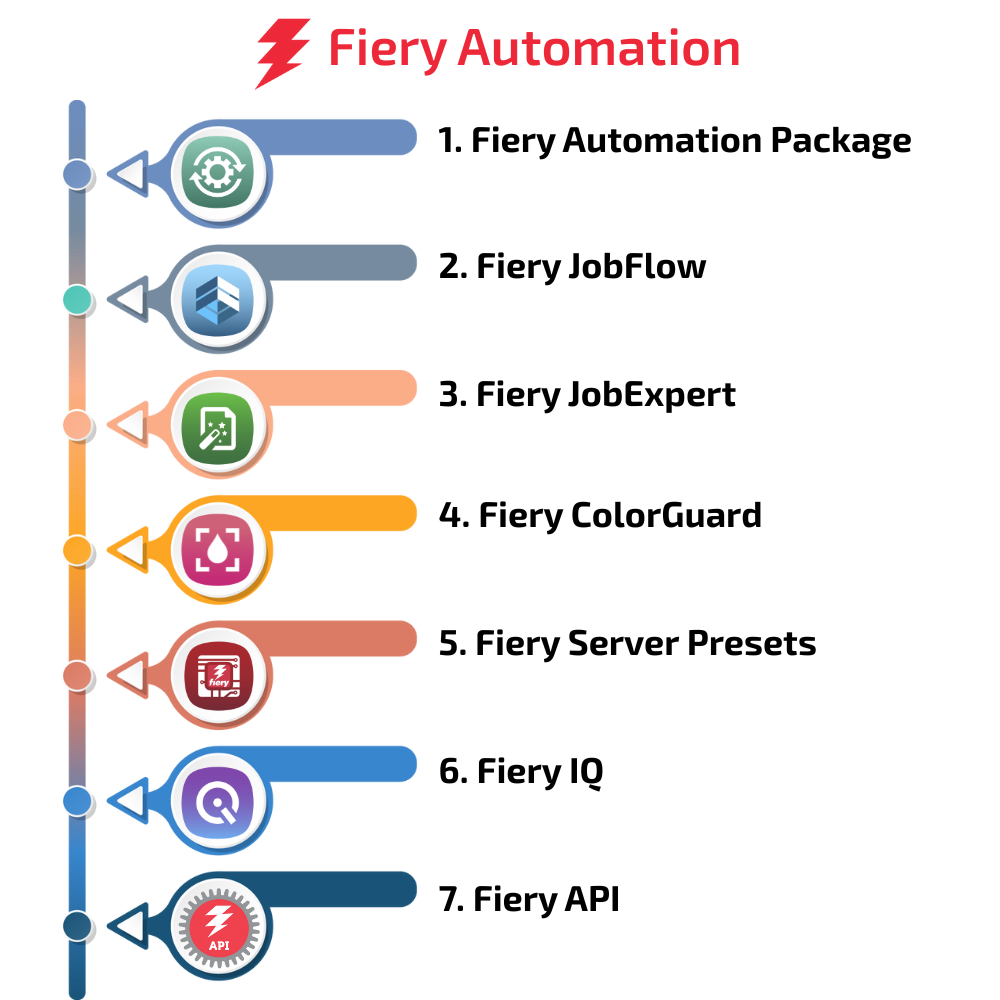

Continuously advancing automation for digital transformation

Throughout our history, Fiery has been laser-focused on innovation not just for its own sake, but to find new ways to solve the problems you face as a print business owner. From color control to easier imposition to more intuitive workflows, we’ve worked for over 30 years to make printing easier.

- Fiery Automation Package: Automate job processes to reduce touchpoints and increase efficiency.

- Fiery JobFlow: Automate prepress workflows for faster, smarter production.

- Fiery JobExpert: Automatically analyze PDFs and apply optimal print settings.

- Fiery ColorGuard: Automate color consistency and accuracy with ease.

- Fiery Server Presets: Automate job property selection for quick, accurate setups.

- Fiery IQ: Automatically capture, monitor, and analyze data to optimize performance.

- Fiery API: Build solutions the way you want them to work with Fiery® products.

A foundational trend we’ve been driving from the very beginning is automation: How can a DFE make your jobs more automated, smoother, and more hands-off? Now, in 2025, the print industry is facing greater challenges than ever before, including shorter-run jobs, faster turnaround times, and staffing shortages, to name a few. Automation remains key. Workflow solutions like Fiery JobFlow and Fiery ColorGuard are specifically designed to automate as much as possible, helping you save time and resources while still delivering the best results.

Future with Fiery AI

As we look toward the future, it is clear that the next great leap in print technology is undoubtedly AI. At Fiery, we see AI not as an abstract pursuit but rather as a natural evolution. It is a part of our long-standing mission—using greater automation to solve the real-world challenges print businesses tackle every day. Two innovative AI-empowered products we’re launching in 2025 will apply the power of AI to real-world bottlenecks in production.

Fiery Scribe uses AI to interpret natural language job requests from emails and automatically convert them into accurate job tickets. A request like “I need 50 booklets with glossy covers” is automatically translated into precise job settings, saving time, reducing errors, and enabling print shops to handle larger workloads effortlessly.

We’re also leveraging AI to transform inventory management with Fiery InkWise. It is a cloud-based assistant that predicts ink consumption and forecasts when to order ink by analyzing historical data. InkWise helps print shops determine and maintain optimal stock levels, eliminating waste and avoiding costly last-minute orders. Early adopters have already seen significant cost savings and smoother workflows.

Expanding into emerging markets

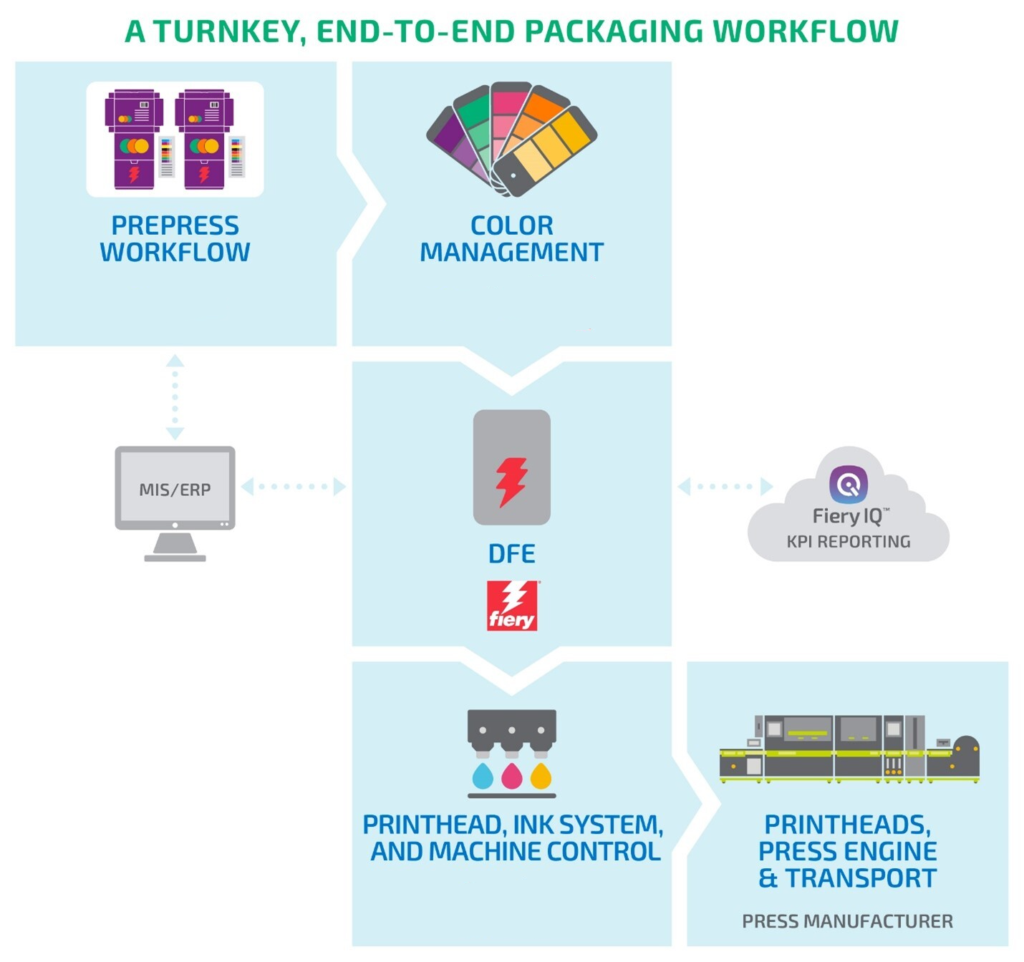

Fiery will continue to lead print innovation in 2025 and beyond. The industry has exciting growth opportunities ahead. Emerging markets like direct-to-film, packaging, signage, and industrial printing are growing rapidly. These applications are in the early stages of digital transformation, with lots of room to grow. Our software solutions in this space are specifically designed to support innovative new presses and help facilitate this transition to digital print.

We created the award-winning Fiery Impress to revolutionize industrial inkjet printing. It offers a scalable, turnkey DFE that integrates effortlessly into manufacturing workflows. Fiery Impress streamlines packaging production while also enabling inline printing on items like handbags or suitcases.

In packaging, Fiery technology powers some of the most exciting new innovations. The Packsize X5 Nozomi is one example. It turns blank corrugated material into custom, right-sized boxes in seconds. This game-changing press streamlines operations for brands. It also delivers personalized, vibrant packaging that stands out on shelves.

Direct-to-Film (DTF) technology is one of the fastest-growing areas of digital print. The power of easy, on-demand custom prints for clothing and goods opens new doors for creativity and customization. It appeals to both small businesses and large-scale manufacturers. Fiery Digital Factory is the leading workflow solution for DTF applications, with hundreds of supported printers. It powers on-demand e-commerce by enabling quick, precise production of custom t-shirts, bags, and other textiles – transforming how businesses meet customer demands.

Leading the way for digital print innovation

For three decades, Fiery has focused on building technologies and solutions that enable production printers to achieve their maximum capabilities. By providing products and tools that solve real-world print shop problems, Fiery has played a pivotal role in shaping the modern print industry. Moving forward, our unceasing commitment to innovation will ensure that the future of printing is faster, smarter, and easier than ever before.

What began as a simple connection between a copier and a computer has become a legacy of digital print innovation. We continue to push boundaries, helping printers meet evolving demands, explore new opportunities, and adapt to an ever-evolving landscape. The future of the print industry is bright—and Fiery will keep leading the way.